Plants and machinery for the production of chestnuts

Machines and equipment for chestnut processing

Anetrini Sas in Carbognano creates machinery for the production of chestnuts but also machines for special processing, machinery for the food industry and prototypes studied and designed in collaboration with the customer for every need.

All our systems are born from a design studied based on specific customer needs and tailored to the environments in which they will be installed.

TRANSPORT AND HANDLING LINE

CONVEYORS

For loading and unloading chestnuts. Customizable features.

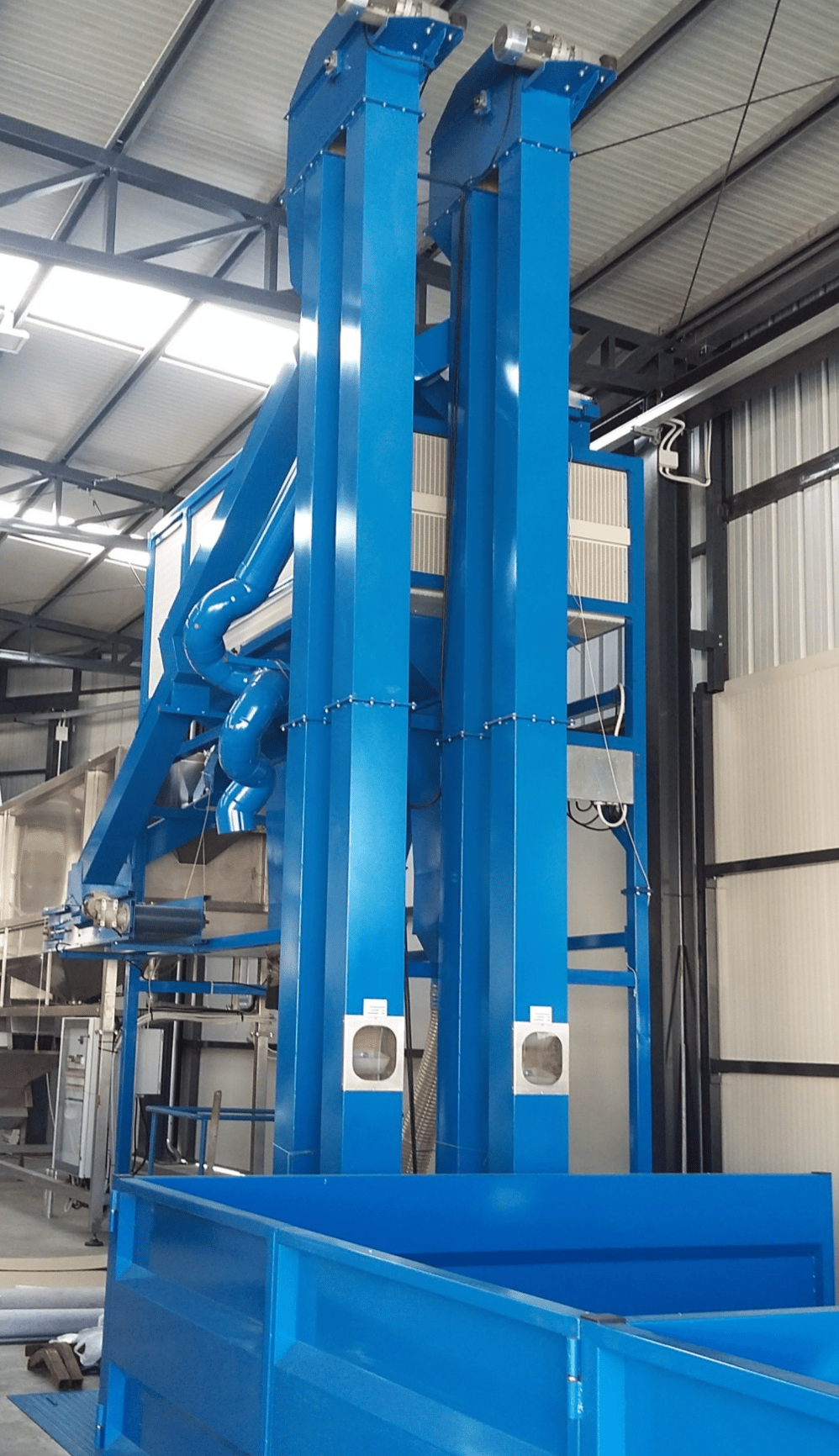

LIFTING BELTS WITH STRUTS

Solution for loading and unloading grit products such as hazelnuts, almonds, chestnuts, allowing you to reach considerable heights, always ensuring high hourly flow rates.

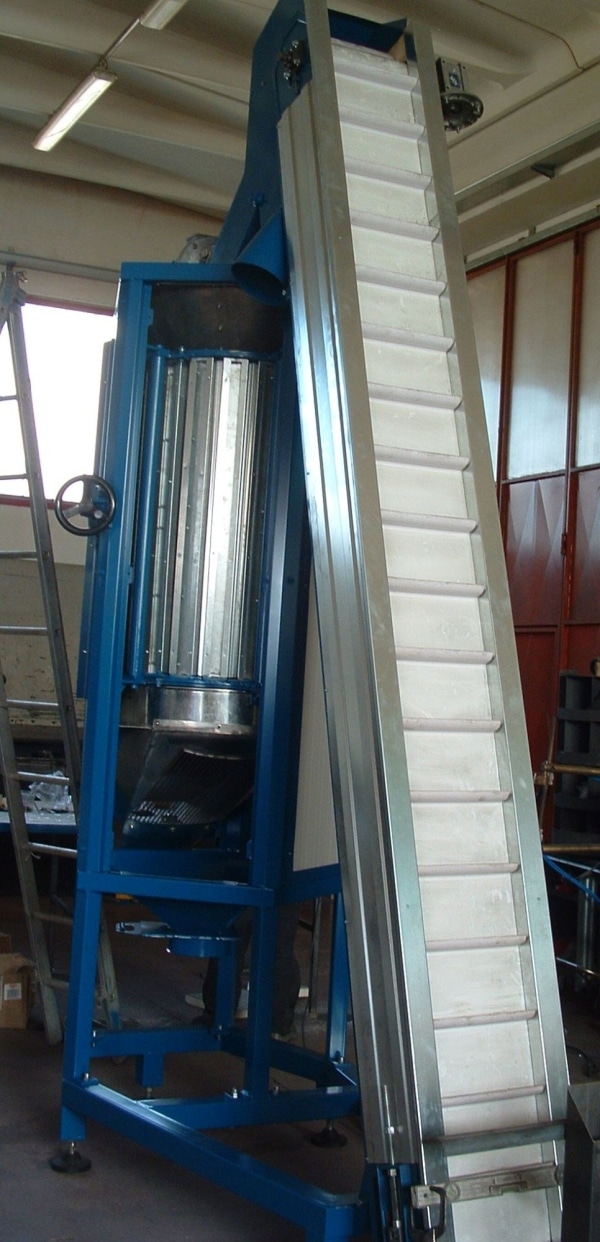

ELEVATORS

IN CUPS

Solution for loading and unloading grit products such as hazelnuts, almonds, chestnuts, allowing you to reach great heights and reduce overall dimensions.

CLEANING LINE

CLEANING SCREEN

Machine created for cleaning chestnuts available in the 1500, 2000, 3000 models, also the 4000 on request.

Customizable with the inclusion of various accessories such as: Loading belt, air cleaner, dust extraction cyclone.

AIR CLEANER

Machinery for the separation of impurities and lighter foreign bodies via air flow.

CHESTNUT SKIMMER

Machinery designed for the bath selection of the good product from the waste product, made of stainless steel.

COMPACT DRY CLEANING SYSTEM

Mobile, complete and towable system for dry cleaning of nuts from impurities, such as soil and foliage. Complete with loading system, sieve cleaning, air cleaning, elimination of stones and product exit and loading system via belt.

DRYING AND POLISHING LINE

DRYING SYSTEM

Solution designed for drying fresh chestnuts after curing.

LONGITUDINAL BRUSHING MACHINE

Longitudinal and transversal brushing machines for chestnut polishing with minimal investment.

POLISHING MACHINE FOR CHESTNUT

Machinery created for chestnut polishing, it can be supplied complete with:

- product loading stand,

- sorting carpet,

- polishing machine filling tape,

- outgoing flat belt.

VERTICAL POLISHER SCIUSCIA

Solution designed for polishing chestnuts with falling product for a high quality result.

SELECTION LINE

CYCLONE SEPARATOR BELT

Caliber sieve with belt version cleaner and cyclone separator.

CALIPERS FOR PRODUCT SELECTION

For the selection of nuts with customisation: sectors, number of screens, openings from manual to pneumatic or radio-controlled, with cyclone for dust extraction; customizable soundproofing panels!

RIBBONS OF CHOICE

Belts for manual selection of the product by operators, with light and lateral guides to eliminate waste. Customizable in length and size.

ROLLER CONVEYORS

Roller conveyor belts can be made with customized lengths and work surface.

TRANSFORMATION LINE

SHELLING AND SORTING MACHINE

Machinery for shelling dried chestnuts and shelling accessory, sorter with suction for dividing waste from whole products. For further information contact the Manufacturer.

SHOCK ABSORBER

Machinery designed to soften chestnuts after drying to obtain the finished product (Mosciarelle)

ENGRAVER

Machinery designed for chestnut cutting, prevents chestnuts from bursting during cooking and allows for optimal cooking.

ACCESSORIES LINE

LOAD STANDS

Stands for product loading by gravity or with linear dispensers.

SILO CONTAINERS

Fully customizable! Product storage systems that can be made to measure in both iron and stainless steel.

STEEL BASKETS

Baskets for containing the product

Machinery design

Guaranteeing customized production strictly depends on the ability of the technical staff to design solutions that are qualitatively valid and always different. When designing the machinery, the staff also takes into account the spaces available in the destination location. Among the instruments for processing chestnuts in Carbognano there are the softener (designed to soften the chestnuts after drying to obtain the "mosciarelle"); the gauges for product selection, complete with customizable soundproofing panels; the strip elevator belts, ideal for loading and unloading operations of grit products, such as hazelnuts, chestnuts, but also almonds. Among the instruments proposed there are also the stand with lateral sides and stainless steel cone, the flour auger, a stainless steel machine useful for dosing and loading chestnut flour, the underground horizontal auger and the one on wheels, which allows adjust the inclination. To conserve the product, we recommend the purchase of silo containers, which are also fully customizable. The company's catalog also includes bucket elevators.

Belts, roller conveyors and cleaners

Of particular importance, among the machinery for processing chestnuts in Carbognano are the tools for polishing chestnuts, complete with a stand for loading the product, a sorting belt, a belt for filling the polishing machine and one for the loading surface. exit. The catalog also includes a particular vertical polisher called "Sciuscià". As regards the production of flour, the chestnut flour mill is specifically designed to obtain the high-quality flour in a simple and effective way. The sorting belts are instead designed for manual selection of the product and are complete with light and lateral guides for eliminating waste. The cleaner is added to the conveyor belts and also acts as a sorter. An air cleaner can also be requested. The vibrating sieve and the shelling machine, the longitudinal brushing machine and the cleaning sieve, the roller conveyor and the skimmer complete the picture of the machinery designed for those involved in chestnut processing. The latter is useful for bath selection of the product and is made of stainless steel. The machinery is offered guaranteeing a complete service, providing for installation, start-up and any emergency intervention. The equipment can also have small dimensions, guaranteeing good performance and low electricity consumption.