Plants and machinery for the production of hazelnuts

Hazelnut processing machines

Anetrini Sas also creates machines for special processing, machinery for the food industry and prototypes studied and designed in collaboration with the customer for every need.

All our systems are born from a design studied based on specific customer needs and tailored to the environments in which they will be installed.

We specialize in the design and construction of systems and machinery for the production of hazelnuts.

TRANSPORT AND HANDLING LINE

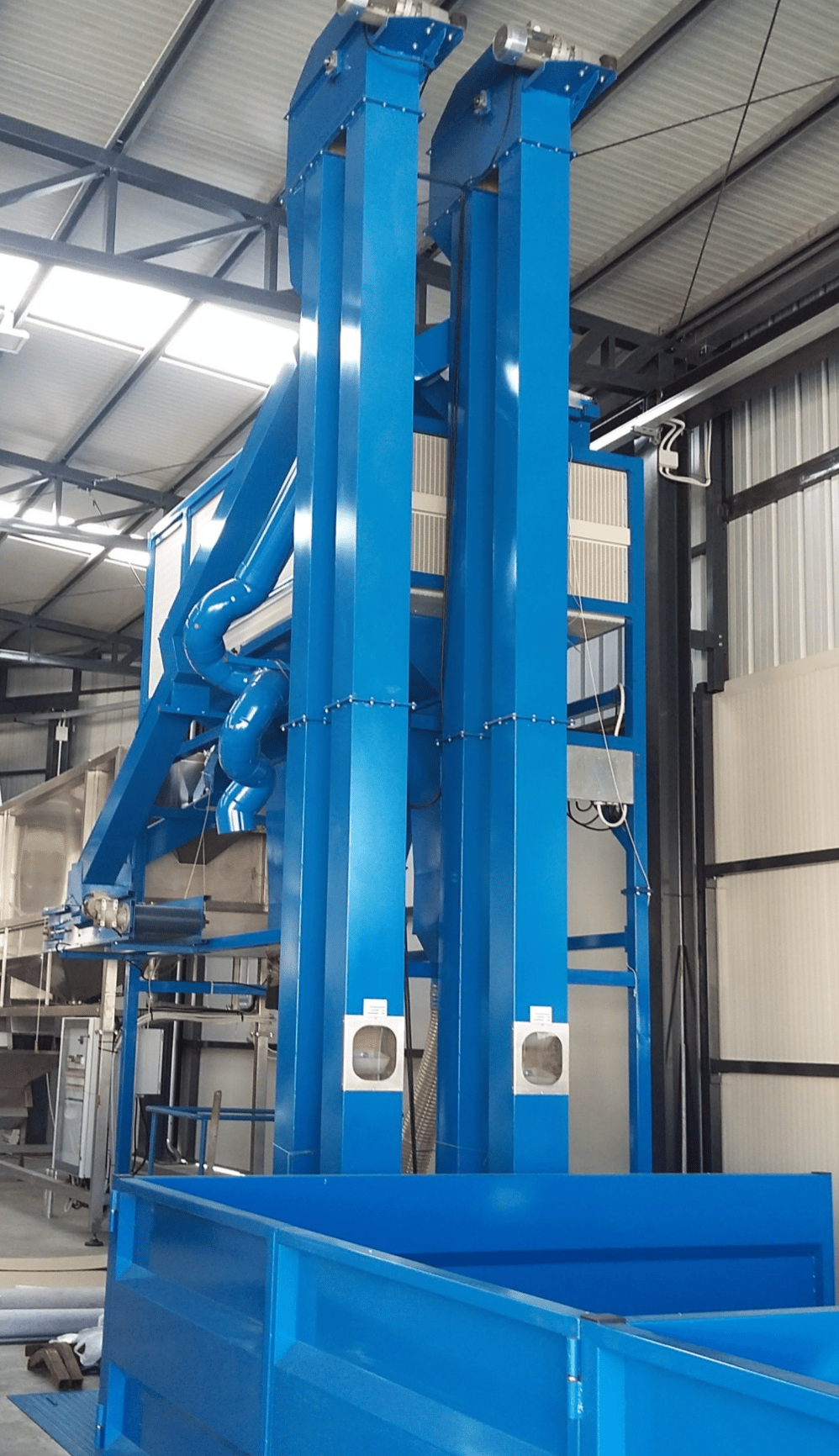

LIFTING BELTS WITH STRUTS

Solution for loading and unloading grit products such as hazelnuts, almonds, chestnuts, allowing you to reach considerable heights, always ensuring high hourly flow rates.

CONVEYORS

For loading and unloading chestnuts. Customizable features.

HORIZONTAL SCREW

Long distance transport of shelled and granular products. High capacity and minimal space requirement.

AUGER ON WHEELS

Long distance transport of shelled and granular products. High capacity and minimal space requirement.

ELEVATORS

IN CUPS

Solution for loading and unloading grit products such as hazelnuts, almonds, chestnuts, allowing you to reach great heights and reduce overall dimensions.

ROLLER CONVEYORS

Roller conveyor belts can be made with customized lengths and work surface.

CLEANING LINE

CLEANER

TO AIR

Machinery for the separation of impurities and lighter foreign bodies via air flow.

DEBRIS SEPARATION SYSTEM (STONES AND SOIL)

For separating nuts from stones and for eliminating soil.

DOUBLE CORVELLO CLEANING SCREEN

Machine created for cleaning chestnuts available in models 1500, 2000, 3000. Customizable with the inclusion of various accessories such as:

- Loading belt,

- air cleaner,

- dust extraction cyclone, etc…

DEBRIS SEPARATION TANK (STONE/EARTH)

For separating nuts from stones and for eliminating soil.

COMPACT DRY CLEANING SYSTEM

Mobile, complete and towable system for dry cleaning of nuts from impurities, such as soil and foliage. Complete with loading system, sieve cleaning, air cleaning, elimination of stones and product exit and loading system via belt.

SELECTION LINE

CALIPERS FOR PRODUCT SELECTION

For the selection of nuts with customization:

sectors, number of screens, openings from manual to pneumatic or radio-controlled, with cyclone for dust extraction, customizable soundproofing panels!

RIBBONS OF CHOICE

Belts for manual selection of the product by operators, with light and lateral guides to eliminate waste. Customizable in length and size.

CYCLONE SEPARATOR

Caliber sieve with belt version cleaner and cyclone separator.

TRANSFORMATION LINE

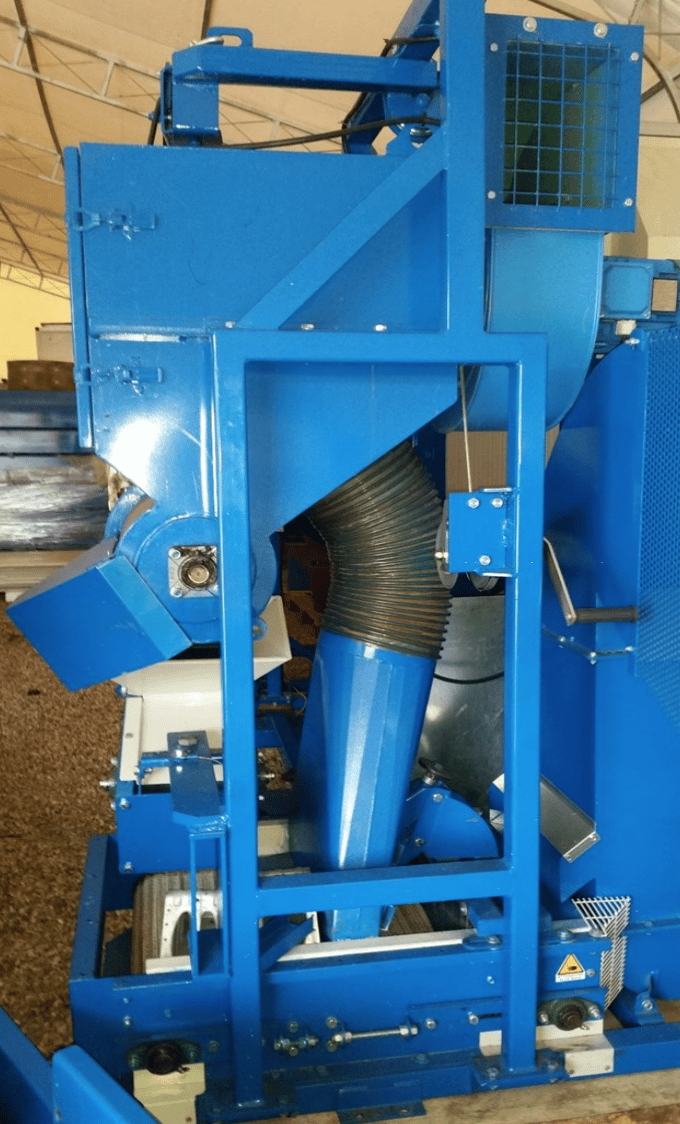

SHELLING PLANTS

Tailored solutions for automated hazelnut shelling with customizable features. For more information contact our offices.

PEEL REMOVER AND COOLER

A solution designed in detail to cool and peel the product (in the case of hazelnuts) after roasting.

VIBRATING SIEVE

Vibrating sieve created for the selection of chestnut grain and flour with product diversification. For more information contact our offices.

ACCESSORIES LINE

STANDS

Stands for product loading by gravity or with linear dispensers.

STEEL BASKETS

Baskets for containing the product

SILO CONTAINERS

Fully customizable! Product storage systems that can be made to measure in both iron and stainless steel.

DRYING LINE

HAZELNUT DRYER

Drying system for woody shell products (in collaboration with the F.lli Zaffrani company) complete with elements for handling and loading the product.

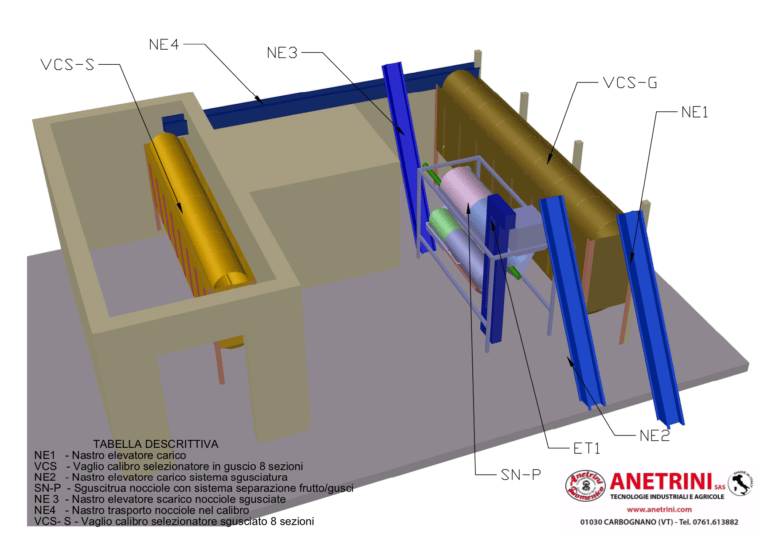

Systems for cleaning and processing hazelnuts

There are many solutions introduced on the market to meet the expectations of dried fruit producers. Think of the numerous intuitions for the hazelnut processing in Carbognano . A significant example is represented by the cleaning and drying system, composed of an underground hopper, an elevator, a double screen cleaning sieve, a washing tank and an elevated screw for loading hazelnuts accompanied by a horizontal version buried for drainage. The in-line dryer is fundamental, together with the conveyor belt. The processing of hazelnuts, like that of chestnuts, also requires the use of calipers, a series of customizable machines to select and sift the dried fruit. The stand with side rails and stainless steel cone is also particularly useful. These are machines designed and made to measure based on customer needs and above all adapted to the environments in which they will be installed.

Automated machinery for hazelnut processing

Similarly to what happens for chestnuts, the catalog designed for hazelnut processing in Carbognano also includes stands for bags and the stainless steel auger for dosing and loading the flour. The horizontal version integrates perfectly with the other instruments within the production chain. Even in this case, silo containers for storing the product are essential: it is from here that the product obtained thanks to the dried fruit transformation process will then be distributed. The bucket elevators and the air cleaner perform an essential function for those involved in hazelnut processing. The conveyor and sorting belts for manual sorting, the vibrating sieve, the manual hazelnut sheller and other tools conclude the list of machinery in question. The preliminary processing phase requires adequate cleaning of the raw material, which is why it is advisable to purchase a tank for washing hazelnuts, thanks to which the nuts are separated from the stones and earth. The slatted elevator belts allow you to reach important heights, guaranteeing noteworthy productivity.